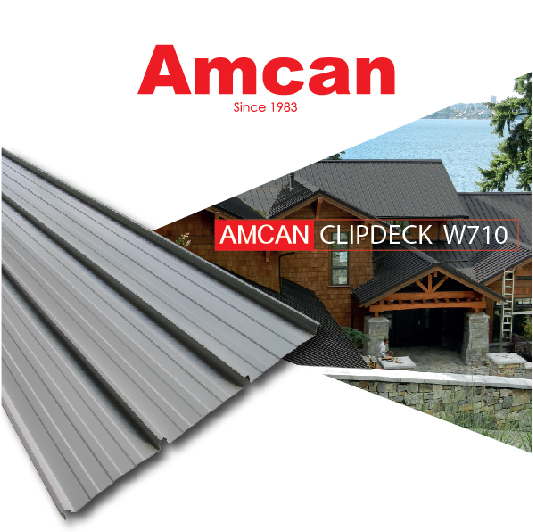

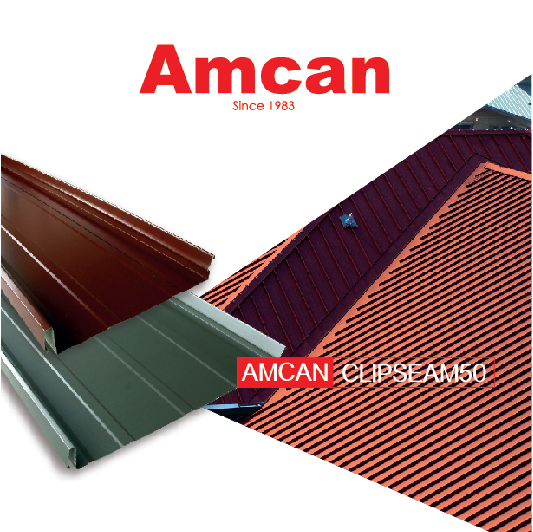

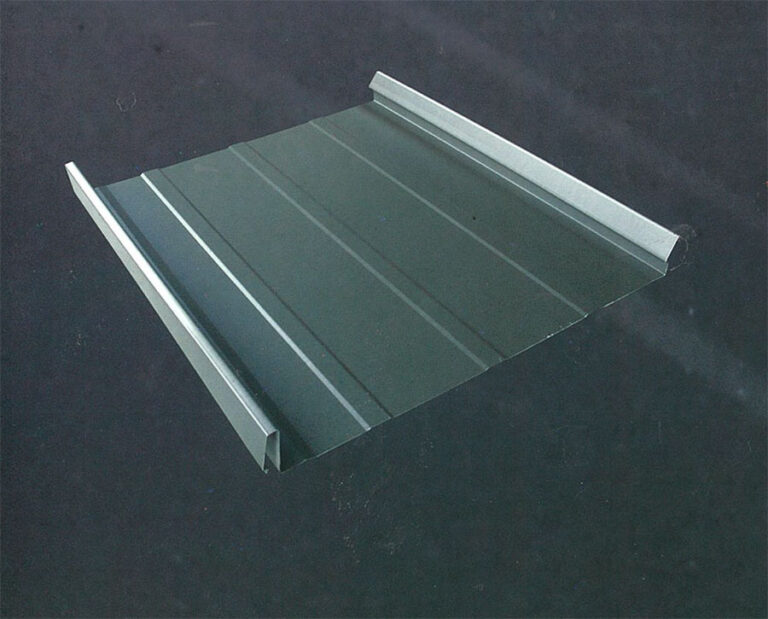

Clipseam 50

Clipseam50 (W288, W445)

High-Ribs Concealed Clip-Locking System

AMCAN CLIPSEAM50, with a 50mm rib, is a uniquely licensed design concept from the USA that features a special concealed fastening system for regions with high rainfall. The screws are completely concealed and protected by the roofing sheet surface wit anti-siphoning gaps and precise rib-snapping action to provide the most watertight and wind resistant roofing system available.

Besides weather resistance, Clipseam50 exhibits the very best in durability as the interlocking fasteners are not exposed to the outside element. The concealed fastener clip system also allows for thermal expansion/ contraction while providing extraordinary holding strength and structural performance.

Material Specification

AMCAN CLIPSEAM50 (W288) is made from premium (GL) 55% Al-Zn Alloy Coated Steel. Material Steel Grade is G550 (550 MPa minimum yield stress).

AMCAN CLIPSEAM50 (W445) is made from premium (GL) 55% Al-Zn Alloy Coated Steel. Material Steel Grade is G550 (550 MPa minimum yield stress).

Profile Properties (Clipseam50-W288)

Maximum Purlins Support (Center To Center)

Maximum Allowable Roof Length (m)

Sprung Curving

Profile Properties (Clipseam50-W445)

Maximum Purlins Support (Center To Center)

Maximum Allowable Roof Length (m)

Sprung Curving

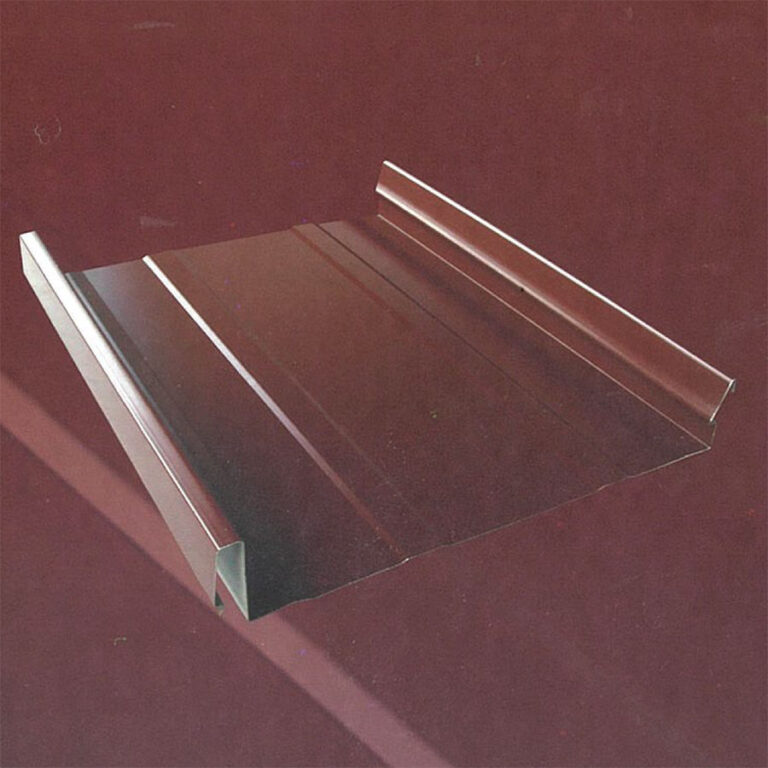

Installation Methods

Step 1

Pull a straight line using a string line. Make sure the string line is in correct alignment to other building elements. Align the first sheet with the string line.

Step 2

Position the clips as shown on the diagram.

Step 3

Fasten 2 fasteners to each clip.

Step 4

Position the second sheet over the first sheet. Make sure that the second sheet snaps in accordance to the diagram as shown. Position and fasten the clips to the following sheet.

Job-Site Rollforming Concept

Extra long roofing sheets can now be rolled on-site to the required length without any end-lapping.

As an added benefit, our rollforming machines are containerized and are therefore very convenient for relocation to different areas of any job-site. This eliminates double-handling and makes it easier to move them over long distances.

AmcanColors Series

Wide range of colour options with different functions and materials

High Performance Polyester

Super Durable Thermal Control

Super Durable 3D In Colour